1. According to the characteristics and functional requ […]

1. According to the characteristics and functional requirements of lipstick paste, there are multiple lipsticks and airtight lipsticks. According to different types of cosmetic packaging, cosmetic packaging materials can also specifically outsource some small accessories.

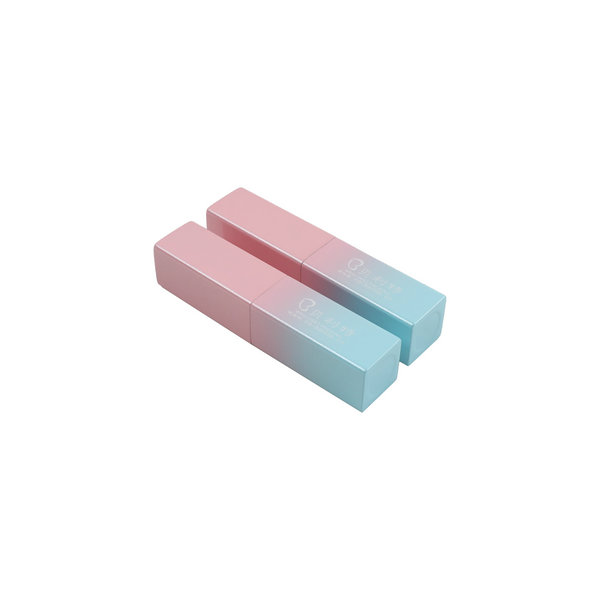

2. According to the size of the matching lipstick, there are pen-shaped lipsticks, lipstick pens, general lipsticks, thin tube lipsticks, and MINI lipsticks.

3. According to the characteristics and functional requirements of lipstick paste, there are multiple lipsticks and airtight lipsticks.

The multi-head lipstick tube packaging is generally a beaded screw structure product, which cleverly uses the main part of the lipstick to extend into a double-bottom interconnected structure. According to different types of cosmetic packaging, cosmetic packaging materials can also specifically outsource some small accessories. The cosmetic packaging material industry and cosmetics are closely linked. Today, the overall homogeneity of the cosmetics industry has increased the value of packaging materials. In recent years, industry insiders have also called for low-carbon and green packaging materials services. Air-tight lipsticks are generally used to satisfy long-lasting lipstick products. The formula contains substances that are easy to volatilize. A chimeric air-tight ring is designed in the lipstick tube cover and middle beam to lock the website content and avoid volatilization. Purpose.

Regarding the surface texture of lipstick tubes, electroplating, bronzing, printing, water transfer and other surface processes are commonly used to achieve metallic effects, shiny gloss and various graphic effects. In addition to the conventional use of plastics for lipstick tube packaging materials, aluminum products can also be used for the main part of high-end products, and aluminum products mostly use an oxidation plating process. The advantage of aluminum parts products is that they have luxurious appearance and texture. However, due to the technological limitations in the stretching and cutting process of aluminum products, it is necessary to pay special attention to the potential safety risks that sharp blades may cause to consumers.

www.aluminumlipsticktube.com